ANSI/OPEI B71.10 Has Been Updated

Compliant Fuel Shut-Off Valves and Plastic Fuel Filters

Fuel system components for outdoor power equipment

Published: December 1, 2020

Last updated: December 31, 2021

What is ANSI/OPEI B71.10-2018?This is the newest edition of the ANSI and OPEI "Off-Road Ground-Supported Outdoor Power Equipment - Gasoline Fuel Systems - Performance Specifications and Test Procedures". This newest version of ANSI/OPEI B71.10 has a November 12th, 2020 implementation date. It applies to all relevant products built after that date.

Who should be interested in this?

- Outdoor Power Equipment (OPE) design engineers

- Manufacturers of small internal combustion engines

- OPE and OEM after-market parts manufacturers and suppliers

Who is ANSI?ANSI, the American National Standards Institute, is a private, not-for-profit organization that oversees the development of voluntary consensus standards for products, services, processes, systems and personnel in the United States. It also coordinates US standards with international standards so that American products can be sold worldwide.

Who is OPEI?OPEI, the Outdoor Power Equipment Institute, is an international trade association that represents power equipment, engine and utility vehicle manufacturers and suppliers. The OPEI developed the original B71.10 in 2008 and then revised it in November of 2018. The new standard goes into effect on November 12, 2020 (two years following the date the new standard was published by ANSI). OPEI is an ANSI accredited Standards Development Organization (SDO) and works with ANSI to develop industry standards.

About OPEI at the ANSI website >>

ANSI/OPEI B71.10-2018 at the ANSI website >>

What does ANSI/OPEI B71.10-2018 mean for fuel shut-off valves and fuel filters?The revised standard now includes new and updated structural integrity testing for inline fuel system components. One of the main goals of this new standard is to prevent the failure of these components.

These updated standards have added new fuel system component certification testing. This new testing was developed to mimic the stresses caused by in-use conditions. These stresses can cause part failures in fuel line components.

Component testing in the revised standards includes testing for fuel shut-off valves and plastic inline fuel filters. This testing covers both basic part integrity (leak testing) and the combinations of forces and exposure that can lead to stress cracking and potential fuel leaks.

ANSI product certification provides independent, third-party confirmation that products meet performance tests set by the relevant ANSI standard. This performance testing is performed by an ISO accredited testing laboratory. Accreditation ensures that testing laboratories have the necessary competency to correctly perform testing and certification.

ISO/IEC 17025 accredited testingISO 17025 is the ISO standard for accrediting independent testing laboratories. This accreditation is issued by ANAB, the ANSI National Accreditation Board. Accredited testing provides standardized, consistent, industry-wide processes to evaluate the performance and quality of critical component parts.

ISO/IEC 17025:2017 at the ISO website >>

ISO/IEC 17025 Laboratory Accreditation at ANAB, the ANSI National Accreditation Board website >>

The ANSI/OPEI certification processSteps to ANSI/OPEI B71.10-2018 fuel shut-off valve and plastic fuel filter certification

- An ISO 17025 accredited independent testing laboratory is selected and contracted to do component testing to the relevant ANSI standard

- Supply the contracted testing laboratory with the required number of samples for each part being tested

- The testing laboratory tests all sample parts using the ANSI/OPEI testing methods and standards

- The testing laboratory reports the test results to the company that contracted for the component testing

- If all the component samples comply with the complete ANSI/OPEI performance requirements, then the parts are compliant with the ANSI/OPEI B71.10-2018 standard

The new ANSI/OPEI B71.10-2018 tests mimic the stresses caused by in-use conditions. The US Consumer Product Safety Commission notified ANSI and OPEI in 2015 that in-use stresses had led to part failures of fuel line components. Because of this, they recommended that additional testing standards be developed including testing standards for critical inline fuel components.

OPEI worked with ANSI to expand and develop these revised standards* and they were published on November 12th, 2018. The new standards come into force November 12th, 2020. Critical fuel line components added to the new testing standards include fuel shut-off valves and plastic inline fuel filters.

*This standard does not purport to address all of the safety problems associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Every sample part must pass every test for certification.

Tests performed*

- Leak testing

- Impact testing

- UV resistance testing

- Fuel resistance testing (E10)

- Fuel shut-off temperature testing

- Fuel shut-off actuation testing

*Each in-use simulation test is followed, in turn, by additional leak testing.

Why use original equipment fuel filters and valves?Using original equipment fuel filters and valves ensures replacement parts’ quality, durability and performance. OEM after-market fuel filters and valves from manufacturers with a proven reputation such as ITW Fastex Filtration and ITW Powertrain Components provide an additional assurance of quality and durability.

Adding certified performance testing to the new ANSI/OPEI B71.10-2018 standard now provides higher confidence in the products that are used in Outdoor Power Equipment and Outdoor Sports and Recreation.

Enhance your brand's reputation

Decrease end user down time and increase user satisfaction by ensuring longer engine life. Provide fuel components engineered and made by ITW Fastex Filtration and ITW Powertrain Components, major automotive-grade North American OPE and OEM after-market manufacturers.

Protect your business from potential risks

Protect end users by using inline fuel components made of strong well-engineered materials. You also get the added assurance that comes from consistent material quality testing as well as modern tooling and assembly techniques.

ITW Fastex Filtration expanded production capacities and improved toolingITW Fastex Filtration has taken steps to increase production capacity due to the certification of select filters and fuel valves to the new ANSI/OPEI standard. They have also redesigned some injection molding tooling. As a partner in this effort to help keep up with OPE and OEM after-market demand for just-in-time ordering, ISM has also committed to carrying deeper stock quantities for all ITW Visu-Filters and Q-Turn quarter turn fuel shut-off valves.

ITW Fastex Filtration Fuel Filter Installation Recommendations >>

ANSI/OPEI B71.10-2018 compliant plastic fuel filters available through ISMFuel filters are critical fuel system components. They help ensure optimal engine performance by capturing contaminants and protecting engines from wear and damage. These ITW Fastex Filtration filters have been tested according to the standards set forth in the ANSI/OPEI B71.10-2018 standard and are compatible with gasoline and gasoline-ethanol blends including E85 flex fuel*.

8408-00-9909, 1/4" Hose Barb Filters >>

- Red nylon 6,6 plastic housing

- 0.85” between hoses (approximated)

- 1.3” diameter (see spec sheet for tolerances)

- 150 micron rated stainless steel mesh screens

- 8.7 gal/hour gravity flow rate (with a 3-1/2" head)

- 1-3/4” overall length (see spec sheet for tolerances)

- 5/16" hose barb connections (1/4" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

8411-00-9909, 1/4" Hose Barb Filters >>

- 0.85” between hoses (approximated)

- Opaque natural nylon 6,6 plastic housing

- 1.3” diameter (see spec sheet for tolerances)

- 60 micron rated stainless steel mesh screens

- 8.2 gal/hour gravity flow rate (with a 3-1/2" head)

- 1-3/4” overall length (see spec sheet for tolerances)

- 5/16" hose barb connections (1/4" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

8416-01-9909, 5/16" Hose Barb Filters >>

- 0.85” between hoses (approximated)

- Clear PCTg type PET plastic housing

- 1.3” diameter (see spec sheet for tolerances)

- 60 micron rated stainless steel mesh screens

- 19.1 gal/hour gravity flow rate (with a 3-1/2" head)

- 1-3/4” overall length (see spec sheet for tolerances)

- 3/8" hose barb connections (5/16" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

What about sintered bronze fuel filters? Where do they fit in, and what about their performance in Powersports and Outdoor Power Equipment?

8419-01-9909, 1/4" Hose Barb Filters >>

- 1” between hoses (approximated)

- Clear PCTg type PET plastic housing

- 0.87” diameter (see spec sheet for tolerances)

- 7.0 gal/hour gravity flow rate (with a 3-1/2" head)

- 2.1” overall length (see spec sheet for tolerances)

- 40 to 70 micron rated sintered porous bronze filter elements

- 5/16" hose barb connections (1/4" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

8423-01-9909, 1/4" Hose Barb Elbow Filters >>

- Clear PCTg type PET plastic housing

- 1” body length (see spec sheet for tolerances)

- 1.8 gal/hour gravity flow rate (with a 3-1/2" head)

- 2.1” overall length (see spec sheet for tolerances)

- 0.86” body diameter (see spec sheet for tolerances)

- 65 to 100 micron rated sintered porous bronze filter elements

- 5/16" hose barb connections (1/4" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

8426-01-9909, 1/4" Hose Barb Filters >>

- 1.4” between hoses (approximated)

- Clear PCTg type PET plastic housing

- 1.2” diameter (see spec sheet for tolerances)

- 7.0 gal/hour gravity flow rate (with a 3-1/2" head)

- 2.9” overall length (see spec sheet for tolerances)

- 125 average micron rated polyester screen filter elements

- 5/16" hose barb connections (1/4" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

Expensive small engines doing tough jobs need the right fuel filter. Which type of filter is better, paper or screen? The answer is "it depends." Fuel flow and other factors determine which kind to use and where to put it.

8437-03-9909, 1/4" Hose Barb In-Line Fuel Filters >>

- 1-1/4” between hoses (approximated)

- Clear PCTg type PET plastic housing

- 1-5/8” diameter (see spec sheet for tolerances)

- 2-3/8” overall length (see spec sheet for tolerances)

- Recommended for use in fuel systems with fuel pumps

- 30 micron rated pleated polymer treated cellulose (“paper”)

- 5/16" hose barb connections (1/4" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

8443-01-9909, 3/16" Hose Barb Filters >>

- 0.8” between hoses (approximated)

- Clear PCTg type PET plastic housing

- 60 micron rated stainless steel mesh screens

- 1-1/8” diameter (see spec sheet for tolerances)

- 3.2 gal/hour gravity flow rate (with a 3-1/2" head)

- 1.63” overall length (see spec sheet for tolerances)

- 1/4" hose barb connections (3/16" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

8479-00-9909, 1/4" or 5/16" Hose Barb Filters >>

- 7-1/2” square inches total filtration area

- Semi-transparent nylon 6 plastic housing

- 1.6” diameter (see spec sheet for tolerances)

- 1.59” body length (see spec sheet for tolerances)

- 3.5” overall length (see spec sheet for tolerances)

- Recommended for use in fuel systems with fuel pumps

- Universal dual hose barbs fit 1/4” and 5/16” ID fuel lines

- 80 micron rated pleated polymer treated cellulose (“paper”)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

8483-00-9909, 1/4" or 5/16" Hose Barb Filters >>

- 7-1/2” square inches total filtration area

- Semi-transparent nylon 6 plastic housing

- 1.6” diameter (see spec sheet for tolerances)

- 1.59” body length (see spec sheet for tolerances)

- 3.5” overall length (see spec sheet for tolerances)

- Recommended for use in fuel systems with fuel pumps

- Universal dual hose barbs fit 1/4” and 5/16” ID fuel lines

- 30 micron rated pleated polymer treated cellulose (“paper”)

- This product complies with the ANSI/OPEI B71.10-2018 standard

- Compatible with gasoline and gasoline-ethanol blends including E85 flex fuel

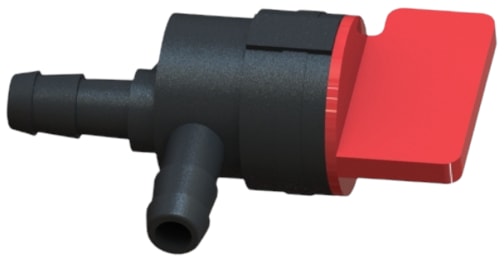

ANSI/OPEI B71.10-2018 compliant fuel shut-off valves available through ISMThese ITW Automotive Q-Turn quarter turn shut-off valves open and close easily with a 1/4 (quarter) turn of their red handle. They comply with the ANSI/OPEI B71.10-2018 standard and are compatible with gasoline and E10 gasoline-ethanol blended fuel*.

7413-02-9909, Q-Turn Right Angle Fuel Valves >>

- Red nylon 6,6 spindle (handle)

- Fluorosilicone (FVMQ) O-ring

- Black heat-stabilized nylon 6,6 body

- Nitrile (Buna-N, NBR) rubber sealing bushing

- Operating temperature range: -22°F to 176°F

- 5.5 gal/hour gravity flow rate (with a 3-1/2" head)

- 5/16" hose barb connections (1/4" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

7423-03-9909, Q-Turn Straight Fuel Valves >>

- Red nylon 6,6 spindle (handle)

- Fluorosilicone (FVMQ) O-ring

- Black heat-stabilized nylon 6,6 body

- Nitrile (Buna-N, NBR) rubber sealing bushing

- Operating temperature range: -22°F to 176°F

- 5.5 gal/hour gravity flow rate (with a 3-1/2" head)

- 5/16" hose barb connections (1/4" ID fuel line recommended)

- This product complies with the ANSI/OPEI B71.10-2018 standard

What do OE manufacturers and designers and OEM after-market distributors get from using ANSI/OPEI B71.10-2018 compliant products?

- Assurance regarding the quality of critical fuel system components

What do end users get?

- Greater safety

- Greater durability

- Greater reliability

Other related blog posts

- Screen vs. Paper Fuel Filters for Small Engines >>

Expensive small engines doing tough jobs need the right fuel filter. Which type of filter is better, paper or screen? The answer is "it depends." Fuel flow and other factors determine which kind to use and where to put it.

- Plastic Fuel Filter Body Materials >>

The choice of body plastic is vital for small inline fuel filters. They must be sturdy, durable, and reliable in Powersports and outdoor power equipment. The best body material plus sound engineering makes all the difference in quality OEM fuel filters.

- Sintered Porous Bronze Fuel Filters, Part 1 - What They Are and Their Use in Small Plastic Inline Fuel Filters >>

Why bronze filter elements for plastic inline fuel filters? Find out more about sintered porous bronze filter elements and their use in small plastic inline fuel filters. ANSI/OPEI B71.10-2018 compliant ITW Visu-Filters Filters for light-duty carbureted vehicles, Outdoor Power Equipment and Powersports use them.

- Sintered Porous Bronze Fuel Filters, Part 2 - How Porous Bronze Filters Are Made and How They Work >>

Details about how sintered porous bronze filter elements are made and how they work: porous bronze particle capture, filter element sintering, small inline filter backwashing, small filter installation and what small filter quality means. ANSI/OPEI B71.10-2018 compliant ITW Visu-Filters use sintered porous bronze filter elements.

- Sintered Porous Bronze Fuel Filters, Part 3 - An FAQ, the Sintering Process and Other Applications >>

An FAQ about depth filtration, porous sintered bronze filter elements and details of the sintering process. Plus, a section about other applications for porous sintered bronze beyond filtration and a list of references used for this three-part article series.