CVN, CVP and CVK Series Check Valves Product Spotlight

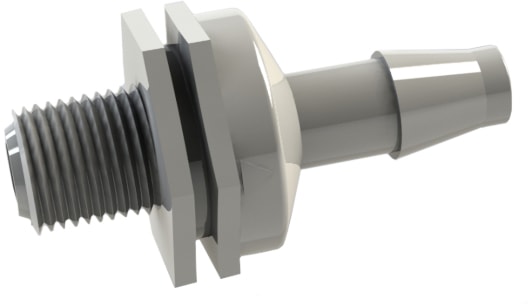

Take a look at one of our miniature low-pressure diaphragm check valves

A product overview of one of ISM’s popular product series

- CVN, CVP and CVK series precision molded check valves >>

These barbed and male NPT thread low-pressure plastic diaphragm check valves come in more than 90 possible combinations of body material, diaphragm material and connection size.

Watch this short video overview about these precision molded diaphragm check valves >>

Compact, low-pressure plastic diaphragm check valves are useful for a wide variety of applications. Their small size, low weight, durability and broad chemical compatibility makes them versatile choices for non-critical low-volume air, gas and liquid backflow prevention.

These USA-made check valves are assembled using sonic welding for exceptional toughness and durability. The series provides an economical and reliable diaphragm check valve option without sacrificing quality.

Compact check valves with a choice of connections

- 1/8-inch male NPT thread to hose barb

- Uniform (same-size barb to same-size barb)

- Enlarging (smaller-size barb to a larger size barb)

- Reducing (larger-size barb to a smaller-size barb)

The hose barb inlets and outlets sizes of these check valves range from 1/8 inch to 3/8 inches (1/8, 3/16, 1/4 and 3/8 inch). The 1/8-inch male NPT thread inlet option comes with this same range of hose barb sizes on the outlet end also.

CVP, CVK series check valve

An important installation note

Check valves need to be oriented correctly to function properly. Flow direction on the CVN, CVP and CVK series check valves is indicated by a raised triangle molded into the check valve bodies.

What does precision molded mean?These fittings are precision molded using proprietary technology that eliminates parting lines on the hose barbs. No parting lines on the barbs means there is no potential flash or mismatch. The sealing surfaces of the hose barb are entirely seamless.

Hose barb critical sealing surfaces

- the barb ridge

- the barb slope

- the barb shaft or shank

Hose barb connections with no potential leak paths between the sealing surfaces of the hose barb and the flexible plastic tubing provide the best leak-proof seals.

Get some insight into hose barb design and how this can affect your application >>

by hose barb check valve

Nylon, polycarbonate, Kynar® (PVDF) or polypropylene body material

- Kynar® (PVDF) is a tough, stable and very non-reactive engineered plastic.

- Polycarbonate is hard and transparent with moderate chemical resistance and good impact resistance.

- Polypropylene is especially economical plus it is highly resistant to solvents and chemicals in harsh environments.

- Nylon provides good durability and chemical resistance along with low permeability to gases. It also performs well at elevated temperatures.

Learn more about Kynar® (PVDF) plastic >

Silicone, Viton® (FKM) or neoprene diaphragm material

- Silicone rubber is very durable and retains its flexibility in extreme heat or cold.

- Viton® (FKM) rubber is resistant to a wide variety of chemicals and fluids, even at high temperatures.

- Neoprene is a strong general-purpose rubber with excellent abrasion resistance and good resistance to chemicals.

NPT thread by hose barb check valve

Very low cracking pressure

The CVN/CVP/CVK check valves have a very low cracking pressure: 6 inches H2O (water). This is equal to only 0.015 psi or 1.49 kPa (kilopascals).

What is “inches of water”?When talking about pressure measurements, inches of water is pretty much what it says. One-inch of water is the pressure exerted by a one-inch high column of water under very specific, defined conditions. Atmospheric pressure, 1 standard atmosphere, is equal to about 407 inches of water.

Inches water or inches of water is used for measuring very small pressure differences. It is a measurement unit primarily used in the United States because it non-metric.

Get tips and insights about check valves and how they workCheck valves, non-return or one-way valves, allow liquid or air to flow in only one direction. Manufacturers make them in a wide range of sizes and types. Tremendous varieties of applications use them to prevent costly or even dangerous backflow.

Even though check valves are widely used for everyday applications, the how and why of check valves and their different designs is not always well understood. Here is some additional information about check valves from the ISM blog:

- How Do Diaphragm Check Valves Work? >>

Many small-bore low-pressure systems use plastic diaphragm check valves. This post describes how the two major types of low-pressure miniature and small-bore diaphragm check valves work.

- Plastic Diaphragm Check Valves – Check Valves Part II >>

Diaphragm check valves are widely used because they are effective, reliable and economical.

- What is Cracking Pressure? >>

Get a better understanding of this critical check valve specification plus advice about selecting check valves. This includes details about how check valve cracking pressure affects reseal pressure and performance. This post also contains information about how check valve selection and sizing can help prevent premature wear.

- More blog articles about check valves >>

If articles like this interest you... please consider subscribing to our blog. You'll receive an email notification whenever we post a new article.

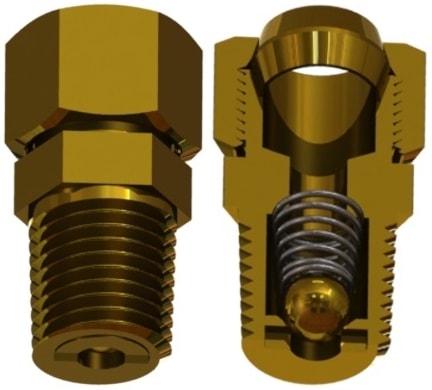

with a cross section view

Some other, related blog posts

- In-line Filters for Miniature Flow Control Component Protection >>

How pairing miniature in-line filters with precision orifices and check valves in flow control systems can boost performance and helps improve reliability.

- Five Tips for Selecting the Right Valve >>

Learn some useful tips for selecting the correct type of valve for your application. Choosing the right valve begins with knowing the role it plays. Knowing its purpose plus a few more key considerations will simplify and speed up any valve selection process. These valve selection tips are a great place to start.

- Checking Out Check Valves – An Introduction >>

How miniature check valves work and function plus descriptions of the most common types. These valves allow liquid or air to flow in only one direction.

- Spring Loaded Check Valves – Check Valves Part III >>

A brief review of the features, uses and characteristics of miniature spring-loaded check valves in air, gas and liquid flow control applications.

Please consider subscribing to our blog. You'll receive an email notification whenever we post a new article.

Are you developing a design for or maintaining a low-pressure (less than 125 psi, 8.6 bar) small-bore air, gas or fluid system? Then ISM has the valve for it.

The ISM Miniature Flow Control Valves catalog includes

- Product specifications

- Photos and rendered CAD images of the valves

- Links to product pages in our e-commerce catalog

Check out our complete lineup of miniature flow control valves >>

Keep in mind we carry thousands of miniature flow control valves. Plus, thousands of related products like connectors, adapters, gauges and so on.

Learn more about the different types of miniature flow control valves you can get from us >>

Diaphragm Check Valves | Spring Loaded Check Valves | Duckbill Check Valves | Plastic Push-In Check Valves | Ball Check Valves | Piston Check Valves | Poppet Check Valves | Modular Check Valves | Plastic Ball Valves | Brass Ball Valves | Stainless Steel Ball Valves | Needle Valves | Metering Valves (Needle) | Metering Valves (Flow Control) | Button-Pilot-Shuttle-Toggle Valves | Stopcocks | Plastic & Metal Relief Valves | Regulators | Pinch Valves

« Go back to the blog homepage